The facility covers a surface of approximately 2.000 m2, divided as follows:

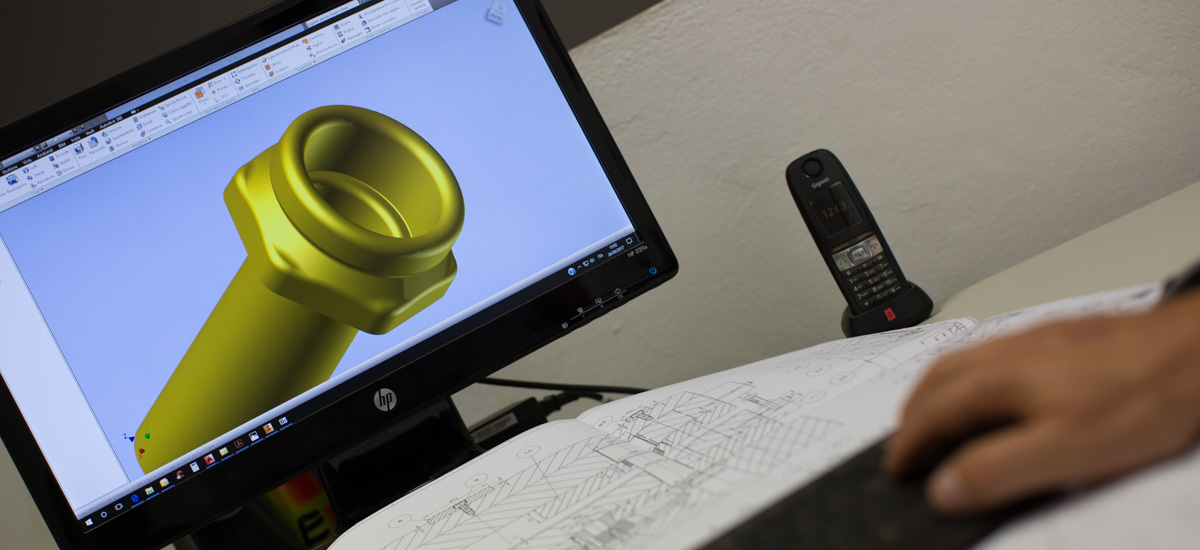

– Technical Office. Composed by an experienced Staff familiar with APQP and PPA methodologies, who operates with CAD/CAM systems and proper documentation at support. That Staff takes care of Product Co-design with the Customer, Prototype Tooling Design, Serial production Tooling Co-design with selected Supplier and more generically, follows the Customer’s Project starting from Feasibility Study and Project Definition to PPA and SOP;

– Toolshop Area. Enable us to be self-capable on Tooling Maintenance, Construction of Prototype tooling and Construction of Simple Serial tooling; it is mainly equipped with traditional lathes, milling and grinding machines, wire EDM;

– Stamping Dept. Composed by C-Frame presses, High-speed stamping presses and Transfer presses with tonnage ranging from 10 to 160; some of them are provided with tonnage monitoring system, all of them can be interfaced with Tooling Safety Systems. Some production lines are equipped with camera system for 100% inspection of the parts produced, most of them are equipped with traditional measuring instruments and go/no go gauges for worker’s self-control activity;

– Quality Lab. Equipped with Optical and 3D measuring machines, Micro-hardness tester, Microscopes, Altimeter and Traditional measuring instruments. Customer’s Claims Management achieved through 4D/8D Methodology and NC Database. Especially for Projects involving Customers operating in the Automotive field, we perform PFMEA and MSA studies as well as, we carry out SPC activity during production process;

– Part Finishing Area. Most of the parts after stamping have to be degreased and/or deburred, for this reason we are fully equipped with Vacuum Degreasing machine, Deburring machines and devices used to determine the degree of cleanliness of the parts.

Deutsch

Deutsch